Shanghai Tower

Structure System

The special shape, remarkable height and complex building environment of the Shanghai Tower have brought great challenges to the structural design. There are no ready-made answers could be found for numerous structural design problems. At the same time, the Shanghai Tower structural design needs not only to ensure the safety, but also to consider structural price as well as the construction feasibility. More importantly, the construction design must satisfy the architectural concept and the functional requirements.

The height of the Shanghai Tower is 632 m; and the height of the construction is 580 m. The diameter of the bottom is 83 m. The height-width ratio of construction is 7.0. The size of the internal core tube bottom, which accounts for 16.6% of the total ground plan area, is 30 m * 30 m; the height width ratio of the internal core tube is 19.3. After a plurality of high-rise building analysis, it is found that for the super high-rise buildings, the height-width ratio of construction and the core tube plays a key factor to affect the whole building. For the Shanghai Tower, the core cube is small in size, resulting in the weakness of lateral stiffness. Therefore, how to effectively improve the external frame structure involved in the overall work of the tower has become a fundamental problem in the selection of structural systems.

Through the comparison of many schemes, Shanghai Tower adopted the system of “mega frame-core tube-outrigger truss" structure. The advantage of this structure system is that the prominent structure efficiency is very high, which can make full use of the structural material to resist gravity and horizontal load, thereby reducing the cost of the structure. Mega frame and the core tube are connected by the outrigger truss in the internal structure strengthening layer (refuge story and facility story), thus forming an integrated structural system.

Fig 1. Strengthened story with outriggers and belt truss (Source:Gensler Design)

Mega frame structure is composed of 8 columns, four corner posts and eight box type space ring trusses. Mega column and corner column are made of reinforced concrete materials. Core tube was designed as a reinforced concrete structure. The section planes change as the changes of architectural function layouts, from the square shapes at low storeys gradually to the cross shapes in high storeys. In order to reduce the axial compression ratio of the wall and increase the shear bearing capacity and ductility of the wall, steel plates are arranged in the basement and the core tube walls, formatting the shear wall structure with a combination of steel and plate.

Table 1. Parameters of super columns and core-tube

(Wang & Wu, 2009)

Fig 2. Structure plan of standard floor and facility floor (Source:Gensler Design)

There are totally six outrigger arranged along the vertical direction respectively in the strengthen layer of Zone Two, Zone Four, Zone Six, Zone Five, Zone Seven and Zone Eight. Outriggers in strengthening layer go through the abdominal walls of core tube, and are connected with the mega columns to increase the anti overturning force.

The vertical load of the second frame columns transfer through each reinforced belt truss to the mega column and corner column, thereby reducing the huge uplift force produced by horizontal load. In addition, in each equipment layer of the strengthen layer, there are many radial trusses bearing the vertical loads of electromechanical equipment as well as the leisure layer, and undertaking the load of the glass curtain wall hoisted by external cantilevered cable. The entire load can be transferred to the ring trusses, mega columns and core cube.

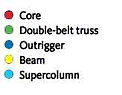

The simplicity of Shanghai Tower's structure is a response to many challenges: a windy climate, an active earthquake zone, and claybased soils. The heart of the structural system is a concrete core, which acts in concert with an outrigger and supercolumn system, with double-belt trusses that support the base of each vertical neighborhood. This makes for an easier and faster construction process --- a vital cost saving for the client.

Fig 3. Mega-frame proved to be an economical approach to construction

(Source:Gensler Design)

Fig 4. Layering of structure, composite floors, inner skin, and exterior curtain wall

(Source:Gensler Design)